+86-13401558444

Views: 6 Author: Site Editor Publish Time: 2026-01-08 Origin: Site

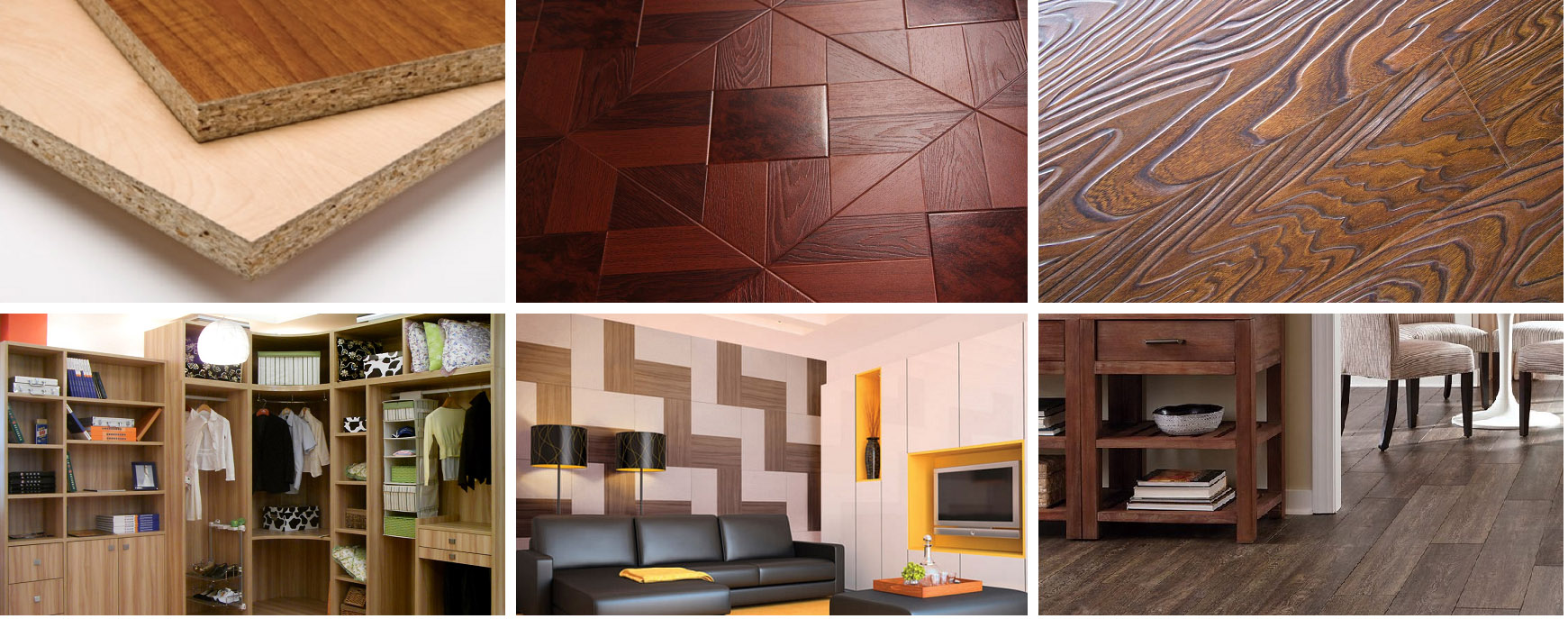

The melamine paper and raw board (PB/chipboard/HDF/MDF/ plywood) are pressed together through melamine lamiante hot press machine with high pressure,high temperature and short cycle time.

The press machine also can press veneer&Phenolic film on MDF,chipboard,plywood.With different pressure,various of textures can be produced,such as glossy,matte,wood grain,marble etc.

The pressure can from 1200T to 3200T (based on 1220*2440mm board).The raw board size : 1220*2440 / 1220*2745 / 1220*3050 / 1830*2440 / 2100*2800 /1830*3660 etc. other size can be customized.

The finished product can be processed to wardrobes,wallboard,flooring,furniture,etc.

Why bother with these machines? Well, in today's fast-paced world, efficiency is king. Melamine laminates are eco-friendlier than solid wood, resist moisture and scratches, and come in endless designs. Manufacturers who produce high-quality hot press lines help businesses churn out products faster, with less waste. Think about it: a good machine can boost output by 20-30%, cutting costs and upping profits. Plus, with global demand for sustainable materials rising, these presses are at the heart of green manufacturing. If you're not using one from a top maker, you might be leaving money on the table.

Quality and Reliability

First off, quality is non-negotiable. Look for manufacturers using high-grade steel and components that withstand daily grind. Reliability means minimal downtime; imagine your production halting because of a faulty part. Top makers test rigorously, offering warranties that give peace of mind. It's like buying a car – you want one that starts every time

Technological Innovations

Innovation keeps things exciting. The best manufacturers incorporate automation, PLC controls, and energy-efficient systems. Features like servo motors for precise loading or AI for temperature control can slash cycle times. If a company isn't evolving, they're falling behind. Ask yourself: does this machine make my life easier

Customer Service and Support

What happens when something goes wrong? Great manufacturers offer stellar support – from installation to training and remote troubleshooting. It's like having a trusty mechanic on speed dial. Check reviews; happy customers mean reliable service.

Cost-Effectiveness and Value

Price matters, but value trumps it. A cheaper machine might break often, costing more in repairs. Top manufacturers balance cost with features, offering ROI through durability and efficiency. Think long-term: a solid investment pays dividends.

1. Yuanfong

Yuanfong is a powerhouse in the industry, known for their robust short cycle presses. If you're looking for reliability wrapped in innovation, this is your go-to.

Company History

Founded in 2007 in Changzhou, China, Yuanfong started small with just a handful of engineers but grew to a 130-person team. They've built their reputation on creating the "Yuanfong" brand, focusing on hydraulic equipment and short cycle presses. Over the years, they've expanded globally, serving furniture and flooring makers worldwide. It's a classic underdog story – from humble beginnings to industry leader.

Flagship Products

Their stars include the Short Cycle Hot Press Machine and Melamine Laminate Press Line. These handle everything from MDF to plywood, with high-speed options like the Clamp Type line. They also offer door skin presses and test machines, all designed for high productivity.

What Sets Them Apart

What makes Yuanfong shine? Their focus on technical innovation and quality assurance. With features like low failure rates and intelligent controls, they reduce downtime. Plus, their professional after-sales team ensures you're never left hanging. Users rave about the energy efficiency – it's like having a machine that saves you money while working harder.

2. Beccor

Beccor is another gem from China, often mentioned alongside Yuanfong for their high-speed lines. They're all about pushing boundaries in short cycle technology.

Company History

Established around 2004 (with ties to similar brands), Beccor has over 16 years in the game. Based in China, they've specialized in full automatic short cycle hot press machines, growing through innovation and customer focus. Their journey involves constant R&D, making them a trusted name in global markets.

Flagship Products

Key offerings include the Full Automatic Short Cycle Hot Press Line and Plywood Hot Press Machine. These are built for laminating melamine on various boards, with options for film-faced plywood too. Their KT Series stands out for speed and automation.

What Sets Them Apart

Beccor's edge? Technological innovation and wide product range. They use cutting-edge digital controls and automated systems for optimized production. High productivity and reliability make them top – think of them as the Ferrari of press lines, fast and precise. Their global supply chain and customization options seal the deal.

3. QiangTong

Qiangtong brings 17+ years of expertise, making them a veteran in melamine press machines.

Company History

Started in 2003 in Wuxi, China, Qiangtong has grown to 100 employees with 30 patents. They've exported to over 20 countries, focusing on R&D with 10% of staff dedicated to it.

Flagship Products

Their melamine laminate hot press machines come in semi and full automatic models, with pressures from 900T to 2800T. Features include servo motors and stainless-steel plates for various finishes.

What Sets Them Apart

Innovations like faster cycle times (down to 10 seconds) and durable designs set them apart. Their focus on labor-saving and high output (up to 120 boards/hour) makes them ideal for busy factories. It's like having a workhorse that never tires.

4. HallMark

HallMark has been in the business for over 16 years, emphasizing full automatic presses.

Company History

Founded in 2004 in Changzhou, HallMark specializes in R&D, production, and sales. They've built a strong service network, serving wood industries globally.

Flagship Products

Their Melamine Press Machines are fully automatic, with high-speed KT Series for MDF and HDF laminating.

What Sets Them Apart

Quality components and stress-analyzed frames ensure durability. Their after-sales service and innovation in heated hydraulic systems make them stand out – reliable like an old friend.

Enhanced Productivity

These machines ramp up output – think 100+ boards per hour. Less waiting, more making.

Long-Term Savings

Durable builds mean fewer repairs. Energy-efficient designs cut bills, like a smart home saving on utilities.

Superior Product Quality

Precise controls ensure flawless laminates, boosting your brand's rep.

Automation and AI Integration

Expect more AI for predictive maintenance, like a car that tells you when to service.

Sustainable Practices

Eco-friendly materials and energy-saving tech will dominate, reducing carbon footprints.

Customization and Flexibility

Machines adaptable to various board sizes, catering to niche markets.

Quick Links

Contact BECCOR